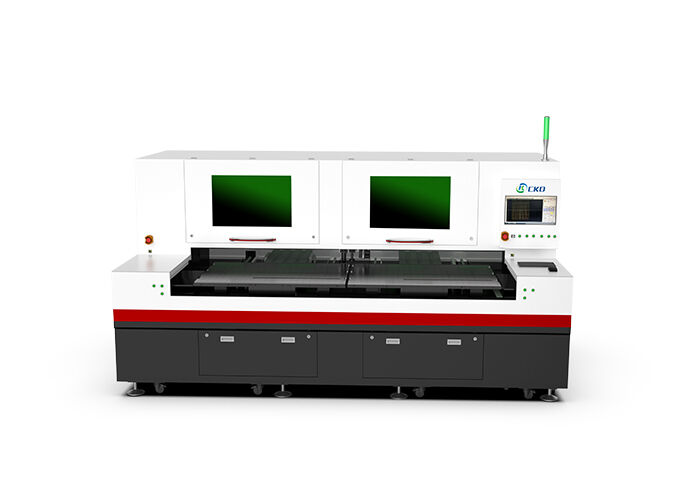

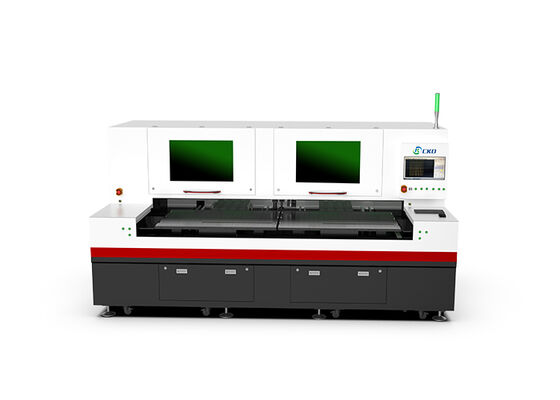

Μηχανή κοπής γυαλιού με λέιζερ που διαθέτει ρυθμιζόμενες παραμέτρους κοπής για να χειρίζεται διαφορετικά υλικά γυαλιού και πάχους με ακρίβεια ± 0,01 mm

-

Βάρος3500 κιλά

-

Ακρίβεια κοπής±0,01 χλστ

-

Βασικά σημεία πώλησηςUltra Fast Picesecond

-

Τύπος λέιζερΥπέρυθρος πικοσυκών

-

Πάχος κοπήςΈως 15 χλστ

-

ΜάρκαCKD

-

Πλάτος κοπής0,03-25 χλστ

-

Πλάτος παλμού<10PS

-

Κατανάλωση ρεύματος≤12KW

-

Μέγεθος εργασίας60*80cm

-

Εφαρμοστέο ΥλικόΑκρυλικό, Γυαλί, Χαρτί, Πλαστικό, Κρύσταλλο

-

softwareCompatibilityAutoCAD, CorelDraw, CAD

-

Συχνότητα εργασίας50HZ/60HZ

-

Μάρκα πηγής λέιζερRaycus

-

Μέθοδος ΨύξηςΥδροψύξη

-

Βάρος μηχανής2000 κιλά

-

Γραφικό σχήμα υποστήριξηςPLT, DXF, AI κλπ.

-

Ποιότητα δέσμηςM^2 <1,2

-

Λειτουργικό ΠεριβάλλονΠερίπου 26 βαθμοί Κελσίου

-

Αποδοτικότητα μηχανημάτων0-500mm/s

-

Γραφική μορφήPLT/DXF/BMP/JPG/GIF/PNG/TIF

-

Τόπος καταγωγήςΚίνα

-

ΜάρκαCKD

-

ΠιστοποίησηISO CE

-

Model NumberCKD-DP6070C-50E CKD-DP6070C-60E CKD-DP6070C-80TE CKD-DP6070C-50ECKD-DP6070S-50E CKD-DP6070S-60E CKD-DP6070S-80TE CKD-DP6070S-80ECKD-DP6070D-50E CKD-DP6070D-60E CKD-DP6070D-80TE CKD-DP6070D-80ECKD-SP6070S-50E CKD-SP6070S-60E CKD-SP6070S-80TE CKD-SP6070S-80E

-

Minimum Order Quantity1

-

ΤιμήNegotiated

-

Packaging DetailsWooden vacuum packaging

-

Delivery Time25-45 days

-

Payment TermsL/C, T/T

-

Supply Ability60sets per month

Μηχανή κοπής γυαλιού με λέιζερ που διαθέτει ρυθμιζόμενες παραμέτρους κοπής για να χειρίζεται διαφορετικά υλικά γυαλιού και πάχους με ακρίβεια ± 0,01 mm

Περιγραφή Προϊόντος:

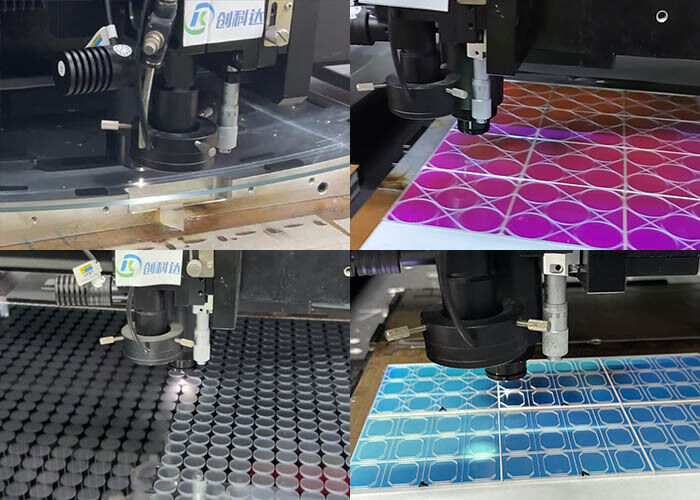

Αυτή η συσκευή είναι μια αποτελεσματική συσκευή κοπής που χρησιμοποιεί λέιζερ υψηλής ενέργειας για την κοπή γυαλιού. Η κοπή στοχεύει στην επεξεργασία σχήματος και χρησιμοποιείται υποβοηθούμενη διάσπαση λέιζερ CO2 για την επίτευξη κοπής και διάσπασης γυαλιού. Η επιφάνεια κοπής είναι λεία, χωρίς γρέζια και δεν απαιτεί δευτερογενή λείανση ή στίλβωση. Η ακρίβεια κοπής είναι ± 0,01 mm και η θραύση άκρων είναι ≤ 5 μm.

![]()

![]()

![]()

Τεχνικές Παράμετροι:

| Μάρκα | CKD |

| Τύπος Λέιζερ | Υπέρυθρο Πικοδευτερόλεπτο |

| Επιτάχυνση | 1G |

| Ελάχιστο Γρέζι Κοπής | ≤5um |

| Ακρίβεια Κοπής | ±0,01mm |

| Σύστημα Μετάδοσης | Ράγα και Πινιόν |

| Υλικό | Γυαλί |

| Συμβατότητα με Συστήματα Αυτοματισμού | Υποστηρίζει την ενσωμάτωση με μεγάλα συστήματα αυτοματισμού, συμπεριλαμβανομένων διεπαφών ρομπότ και συστημάτων αυτόματης φόρτωσης/εκφόρτωσης. Υποστηρίζονται τυπικά βιομηχανικά πρωτόκολλα επικοινωνίας (όπως Modbus, OPC). |

| Πλεονεκτήματα | Υψηλής ταχύτητας κοπή ακανόνιστου σχήματος Υψηλή ποιότητα κοπής, χωρίς κωνικότητα, χωρίς γρέζια, μικρό τσιπάρισμα Υψηλό ποσοστό απόδοσης, χαμηλή κατανάλωση και εξοικονόμηση ενέργειας Χωρίς ρύπανση, χωρίς σκόνη και χωρίς απόβλητα |

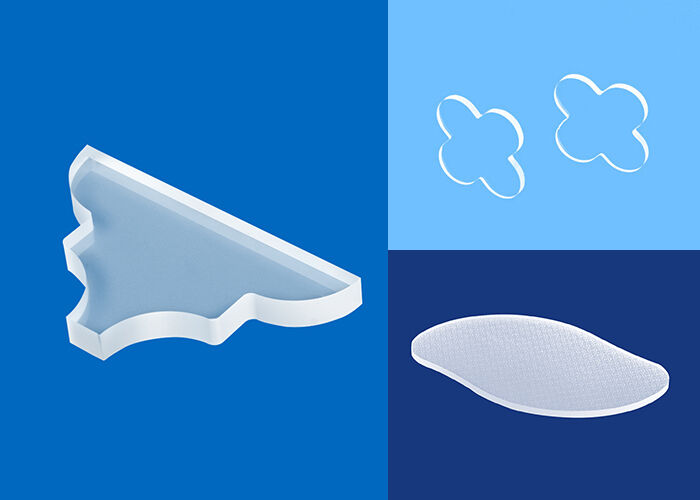

Εφαρμογές:

Μπορεί να επεξεργαστεί "εξαιρετικά καθαρό γυαλί, κανονικό λευκό γυαλί, γυαλί πυριτικού βορίου υψηλής περιεκτικότητας, γυαλί χαλαζία", κ.λπ., κάλυμμα κινητού τηλεφώνου, κάλυμμα γυαλιού αυτοκινήτου, κάλυμμα γυαλιού κάμερας, κ.λπ., κάλυμμα ζαφειριού κινητού τηλεφώνου, κάλυμμα ζαφειριού κάμερας, λωρίδα φωτός ζαφειριού, γυαλί K9, κοπή φιλμ φίλτρου, κοπή ανακλαστήρα, κ.λπ. Οπτικό γυαλί.

![]()

![]()

Εισαγωγή στην εταιρεία:

Η Shenzhen CKD Precision Mechanical & Electrical Co., Ltd. ιδρύθηκε το 2010. Είναι κατασκευαστής εξοπλισμού λέιζερ Ultrafast και πάροχος λύσεων νέας έξυπνης κατασκευής αυτοματισμού που ενσωματώνει Ε&Α, παραγωγή, πωλήσεις και εξυπηρέτηση. Μετά από περισσότερα από δέκα χρόνια βαθιάς καλλιέργειας και συσσώρευσης, η εταιρεία έχει συσσωρεύσει περισσότερα από 70 διπλώματα ευρεσιτεχνίας, πέρασε την πιστοποίηση CE, την πιστοποίηση συστήματος διαχείρισης ποιότητας 1S09001 και την πιστοποίηση συστήματος διαχείρισης πνευματικής ιδιοκτησίας. Είναι μια εθνική επιχείρηση υψηλής τεχνολογίας και μια επιχείρηση Shenzhen Professional, Refined, Special και Innovation.

Η εταιρεία διαθέτει ένα εργαστήριο λαμαρίνας, ένα εργαστήριο μηχανουργικής κατεργασίας, ένα εργαστήριο συναρμολόγησης και ένα εργαστήριο ανάπτυξης και αποσφαλμάτωσης διεργασιών, που καλύπτει Ε&Α, Παραγωγή, Δοκιμές, Πώληση & εξυπηρέτηση μετά την πώληση.

Μέχρι στιγμής, η εταιρεία διαθέτει μια ισχυρή ομάδα Ε&Α που ασχολείται με τον σχεδιασμό δομών λέιζερ και την τεχνολογία εφαρμογών λέιζερ εδώ και πολλά χρόνια. Με μια ισχυρή ικανότητα Ε&Α και βασική τεχνολογία λογισμικού, η εταιρεία έχει επιτύχει καινοτομία και ανακάλυψη στην τεχνολογία προϊόντων σε τομείς όπως η εξαιρετικά γρήγορη κοπή με λέιζερ, η διάτρηση με λέιζερ, η επισκευή οθόνης TFT-LCD με λέιζερ, η πλαστική σφράγιση και αποκόλληση ημιαγωγών, η λείανση διαμαντιών, η συγκόλληση με λέιζερ και η σήμανση με λέιζερ. Ειδικά στην επεξεργασία σκληρών και εύθραυστων υλικών όπως γυαλί και κεραμικά, επισκευή TFT-LCD, πλαστική σφράγιση και αποκόλληση ημιαγωγών, καθώς και λείανση διαμαντιών και άλλες αυτοματοποιημένες νέες έξυπνες κατασκευές, παρέχουμε στους πελάτες λύσεις χαμηλού κόστους, υψηλής ποιότητας και υψηλής απόδοσης, συμβάλλοντας στον πελάτη με προστιθέμενη αξία, καινοτομία και ανάπτυξη.

![]()

![]()

![]()

Συσκευασία και Αποστολή:

Συσκευασία και αποστολή προϊόντων για τη μηχανή κοπής γυαλιού με λέιζερ

Η μηχανή κοπής γυαλιού με λέιζερ συσκευάζεται προσεκτικά για να διασφαλιστεί ότι φτάνει με ασφάλεια και σε άψογη κατάσταση λειτουργίας. Κάθε μονάδα είναι ασφαλώς τυλιγμένη με προστατευτικά υλικά για την αποφυγή ζημιών κατά τη μεταφορά, συμπεριλαμβανομένης της επένδυσης αφρού και των ανθεκτικών πλαστικών καλυμμάτων. Στη συνέχεια, το μηχάνημα τοποθετείται μέσα σε ένα στιβαρό ξύλινο κιβώτιο σχεδιασμένο να αντέχει σε σκληρό χειρισμό και περιβαλλοντικούς παράγοντες.

Για πρόσθετη ασφάλεια, η συσκευασία ενισχύεται με ατσάλινους ιμάντες και υλικά απορρόφησης κραδασμών. Όλα τα ευαίσθητα εξαρτήματα και αξεσουάρ συσκευάζονται ξεχωριστά και επισημαίνονται καθαρά για εύκολη αναγνώριση κατά την παράδοση.

Προσφέρουμε πολλαπλές επιλογές αποστολής για να καλύψουμε τις ανάγκες σας, συμπεριλαμβανομένων αεροπορικών εμπορευματικών μεταφορών, θαλάσσιων εμπορευματικών μεταφορών και υπηρεσιών ταχυμεταφορών. Η ομάδα logistics μας συνεργάζεται με αξιόπιστους μεταφορείς για την έγκαιρη και αποτελεσματική παράδοση παγκοσμίως. Παρέχονται πληροφορίες παρακολούθησης για όλες τις αποστολές για να σας ενημερώνουμε καθ' όλη τη διάρκεια της διαδικασίας παράδοσης.

Πριν από την αποστολή, κάθε μηχανή κοπής γυαλιού με λέιζερ υποβάλλεται σε διεξοδική επιθεώρηση και δοκιμή για την εγγύηση της ποιότητας και της απόδοσης. Διατίθενται επίσης προσαρμοσμένες λύσεις συσκευασίας κατόπιν αιτήματος για την κάλυψη συγκεκριμένων απαιτήσεων.

Εμπιστευτείτε μας για να παραδώσουμε τη μηχανή κοπής γυαλιού με λέιζερ με ασφάλεια, ασφάλεια και σύμφωνα με το χρονοδιάγραμμα.

![]()